The MatchingPro functionality in LYNX accelerates the HM process through improved understanding of the HM quality (error) relative to individual model parameter changes.

The effects on the HM quality of a large range of values for multiple model parameters can be rapidly accessed after a few preliminary simulation runs. Genetic algorithms find the global minimum. This results in recommended parameter values for further improvement in the HM quality. The entire MatchingPro process, which is highly automated, requires engineering judgments from the user at key steps in the process. A patent is pending on the MatchingPro methodology.

More Information

MatchingPro Functionality

MatchingPro® is the latest innovative history matching (HM) technology from NITEC that is very easy to use, fully utilizes available computing resources, and provides fast, reliable HM solutions. MatchingPro only requires a reservoir simulation model combined with historical production, injection, and pressure data to accurately and efficiently determine the best HM solution based on the selected HM parameters. No thinning of the historical data is required.

MatchingPro can function in auto or manual modes to achieve a high-quality HM solution. In the MatchingPro auto mode, simulation cases are designed, run, and evaluated without user intervention. The process is expedited by utilizing multiple computer CPUs, when available.

MatchingPro’s cutting edge technology makes use of Artificial Neural Networks (ANN), Genetic Algorithms (GA), and statistical methods. These algorithms quickly reveal the complex relationships among the HM parameters and the simulation results (the mismatch in simulated versus historical volumes and pressures). MatchingPro quantifies the quality of each HM case and recommends the best combination of HM parameters to achieve the best HM solution. MatchingPro can also determine multiple HM solutions (model characterizations) and provide a quantification of their probabilities of occurrence.

The MatchingPro Process: Auto Mode

The observed performance data sets are easily loaded into MatchingPro. This includes: individual well monthly production or injection volumes; static reservoir pressures from build-up tests or shut in wells; and dynamic bottomhole pressures from flowing wells.

The HM parameters and their associated physical ranges are defined via an interactive window. The parameters can be continuous or discrete by defining them as real (linear or logarithmic), or as integer.

In order to search for the best solution (defined as a set of HM parameters) or multiple solutions, an objective function is defined. The objective function weighs each “mismatch variable” (oil, water, and gas production, injection, and pressure) for use in the minimization calculations. The mismatch can be minimized for selected wells, gathering centers, or the total field. MatchingPro includes a default objective function that is applicable to most situations. The objective function can be modified at any time during the history matching exercise (auto or manual mode) and does not require repeating of the simulation cases or regeneration of the correlation model.

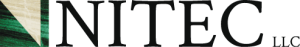

MatchingPro commences a pre-determined iterative process. Simulation cases are created, run, analyzed, and displayed as each case is completed until the entire routine is finished. Once all of the runs are executed, the final plot reveals the best HM solution.

Completed History Match Cases (Objective Function by Simulation Case)

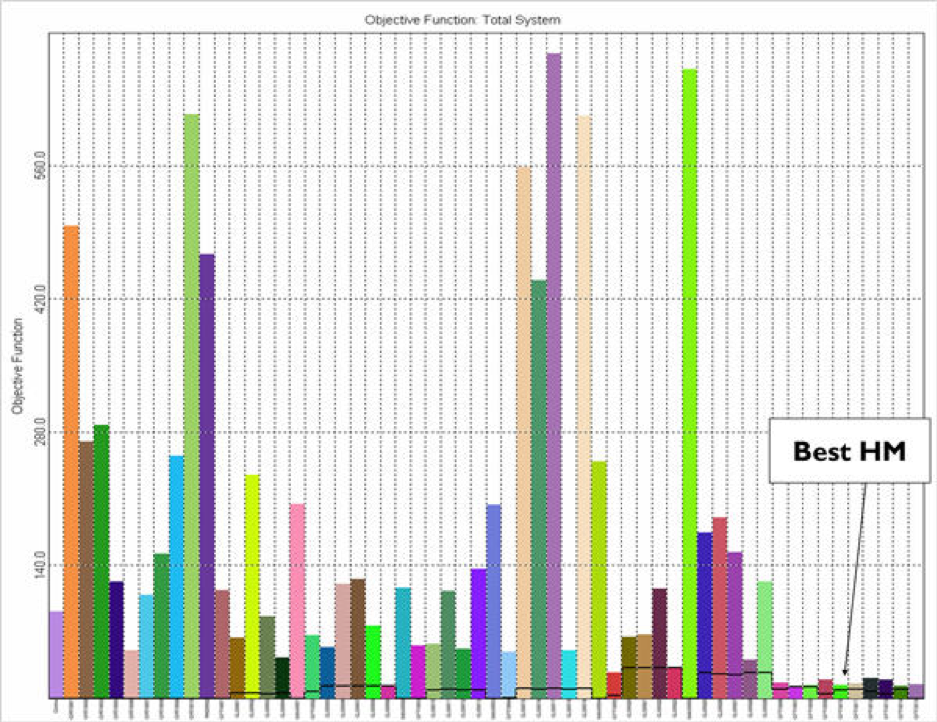

First/Best History Match Cases (Field Production Rate vs. Time)

Multiple History Match Solutions

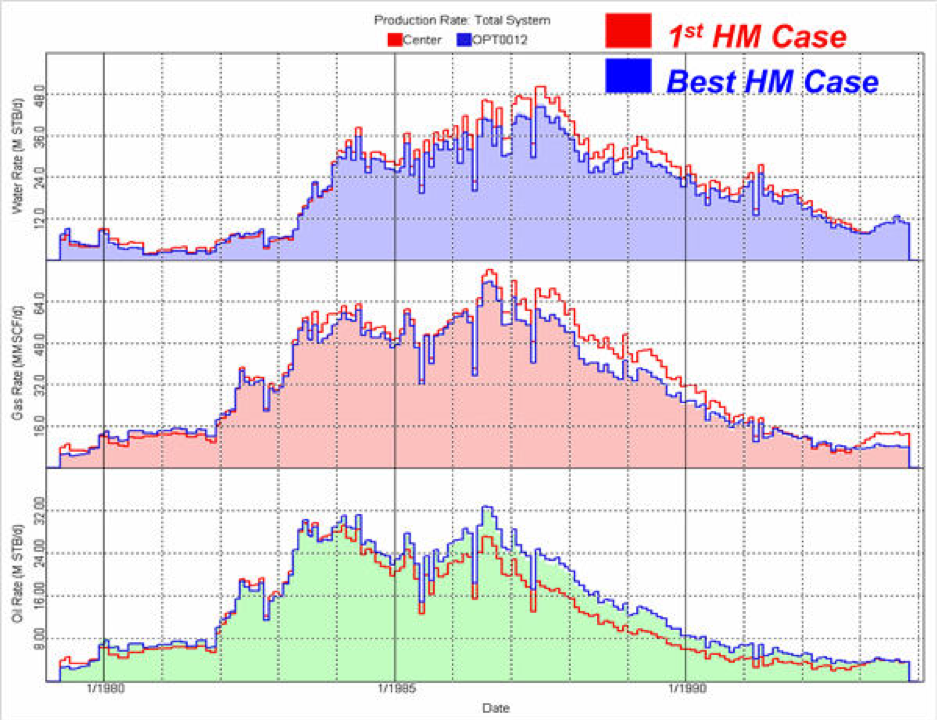

One of the unique features of MatchingPro is the ability to generate multiple history match solutions for the same HM problem. MatchingPro also calculates the probability of occurrence of the set of HM parameters determined for each acceptable HM solution. The minimized objective function value is typically very similar for each solution. However, these different solutions may result in very different performances in the prediction cases. This highlights the well-known non-uniqueness of HM solutions.

Once the MatchingPro process has completed and a satisfactory history match solution has been found as exhibited by the very low objective function value, the user can utilize MatchingPro’s solution clustering algorithm to determine multiple HM solutions. These solutions may be equally acceptable from the perspective of the objective function (overall HM error), but will have different values for the individual HM parameters.

The user can utilize MatchingPro’s Monte Carlo technology to sample the correlation model, say one million times. From this sample, the user can request the number of multiple HM solutions desired. MatchingPro’s clustering technology groups these solutions accordingly and calculates the probability of occurrence for each.

Each of these solutions will have different HM parameter values, but the objective function value will be very similar indicating an equally acceptable solution.

While the HM parameter values appear similar, experience indicates that very minor differences in the final HM parameters can result in significant variations in prediction results.

A display of the predicted performance for a well in a large field where three HM solutions were generated shows the predicted performance for the same operating scenario can be quite different for the three cases.

Common Prediction for Multiple HM Solutions