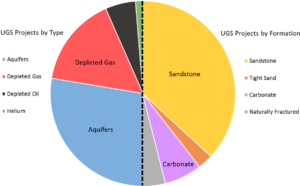

NITEC has been providing reservoir modeling and decision support solutions for Underground Gas Storage (UGS) operators since 1997.

Our staff has over 30 years of experience evaluating gas storage reservoirs for new field development, due diligence/field acquisition, inventory verification, and reservoir modeling.

These projects focused on optimizing operations, storage expansion, gas migration control, deliverability improvement, and infrastructure investment for all types of UGS reservoirs – depleted oil/gas & aquifers in sandstone & carbonate formations.

Locations of USA Gas Storage fields where NITEC has consulting experience

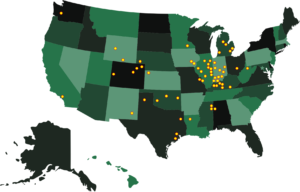

Example of an UGS project modeling a storage reservoir with a gas recovery zone

Related Projects:

Storage Expansion in Faulted, Fractured Carbonate (OK, USA):

NITEC history matched a dual-porosity simulation model for this 40 BCF naturally fractured and faulted carbonate gas storage reservoir. The study required developing a new reservoir characterization for the natural fractures using NITEC fracture characterization technology. The model was used to evaluate the deliverability benefits from in-fill wells vs well workovers vs additional compression. (58 wells, 28.2 BCF working gas, 660 MMCF/D)

Improve Deliverability with In-fill Wells (TX, USA):

NITEC developed the reservoir characterization from old vintage well logs for this 65 well, 75 BCF gas storage field which was input into the simulation model. The model was successfully history matched and provided deliverability predictions for 15 in-fill wells increasing storage capacity to 96 BCF working gas with a peak rate of 1,230 MMCF/D

Vertical Well Replacement with Horizontal Wells (KY, USA):

NITEC completed a storage optimization study for a large storage field in Kentucky, initially with over 150 old vertical wells, 135 BCF Total gas and 730 MMCF/D peak deliverability. The history matched model was used to evaluate replacing old vertical wells with horizontal wells, surface gathering system improvements (12 branched/looped lines), and additional compression power. After the evaluation, the field incorporated 13 horizontal wells, increasing deliverability to 1,030 MMCF/D, and improving working gas to total gas efficiency.

Gas Migration Control (Midwest USA):

NITEC developed a complex reservoir simulation that involved two aquifer storage formations and an oil production/gas recovery formation above the main storage zone. This field was old with vintage well logs and data records. The objective for the study was to determine the volume of gas migration into the recovery formation over the past 50 years and provide operational strategies to minimize future gas migration.

Impact of 3rd Party Operations (KY, USA):

NITEC evaluated the impact of 3rd party E&P operations outside the storage boundary on this storage fields gas recovery-zone in the cap rock above the aquifer storage field. The storage and gas-recovery operations had been stable for many years until recent E&P activity in the surrounding areas began targeting the shale caprock. NITEC was able to confirm that the E&P activity was negatively impacting the storage operations and developed a counter-strategy to protect the stored gas in the recovery zone.

Increase Working Gas, Control Migration, In-fill Wells (NE, USA):

NITEC conducted an integrated reservoir study in a complex fluvial sand gas storage field to provide operational strategies for controlling gas migration between the main storage structure and a small low productivity structure and improving deliverability and working gas capacity. The project resulted in 10 new wells which increased deliverability by 75 MMCF/D and increased working gas by 10 BCF and provided a strategy to eliminate the gas migration.

Buyer Due Diligence – Depleted Oil Converted to Gas Storage and Oil Production (TX, USA):

NITEC conducted a detailed evaluation of this complex gas storage field with oil production. The field was a faulted anticline resulting in partial compartmentalization impacting the communication from two portions of the gas bubble and the downslope oil leg. The valuation was dependent on confirming well productivity/deliverability rates and increased oil production with the storage expansion. NITEC was able to identify key areas of uncertainty regarding the production claims as well as regulatory issues that were used in the client’s valuation model.

Buyer Due Diligence – Depleted Gas Developed into Gas Storage (CO, USA):

NITEC represented the buyer in technical assessment meetings as part of our evaluation process. This field was comprised of two dome shape lobes connected through a syncline. The key issue for this field was to assess the connection between the two domes and additional base gas requirements as well as evaluate reservoir containment risks due to unmapped adjacent areas. NITEC provided the client with valuable insight in the stratigraphic complexities of the region.

Buyer Due Diligence – Aquifer Gas Storage Development – 4 Fields (WY, USA):

NITEC completed a detailed evaluation of 4 small aquifer gas storage fields packaged together. The project required different modeling technologies: material balance-hysteresis with and without aquifers, volumetric storage model with surface network and compression, and a simulation model. The objectives were to determine the recoverable working and base gas for each field and to model various storage volumes and deliverability strategies.

Inventory Assessment Audit – 5 Fields (Midwest USA):

NITEC conducted an inventory verification/assessment audit for a client’s 5 gas storage fields which were a mixture of aquifer and depleted gas storage. The audit consisted of reviewing the client’s current inventory verification methodology and data and performing an independent evaluation of each storage field’s inventory behavior for the 6 year audit period.

Inventory Assessment/Verification Study– 8 Fields (Midwest USA):

NITEC performed a detailed inventory assessment study for this client’s 8 gas storage fields. The purpose of the study was to evaluate the impact on inventory and storage operations that may have occurred due to changes in the client’s methodology for tracking and accounting for lost and unaccounted for (LUF) gas. All 8 fields were aquifer storage fields. NITEC evaluated each fields inventory with an aquifer material balance model and modified Pressure-Content (Hysteresis) methodology to determine the impact on the inventory, storage field deliverability, and to make appropriate recommendations.

Old Carbonate Oil Field (SE USA):

NITEC conducted a detailed field study to evaluate the gas storage potential of a deep depleted oil carbonate reservoir. The study included geology and petrophysics analyses to create a reservoir characterization model for a detailed reservoir simulation study. The simulation model history matched the original depletion period, matching oil, water and gas rates, and pressure observation data. Due to the depth and anticipated operating pressure for the storage operations, a compositional model was required to accurately predict the miscible interactions between the gas and remaining oil and the resulting oil production. The results were used to design the liquid handling requirements for the surface facility.

Old Heavy Oil Field (Argentina):

NITEC performed a detailed field study to determine the gas storage potential of a depleted oil fluvial sand reservoir. The study included geology and petrophysics analyses to create a reservoir characterization model for a detailed reservoir simulation study. The simulation model history matched the original depletion period, matching the oil and gas rates and pressure data. The optimal development required groups of 3 horizontal wells with gas injection used to sweep the remaining oil into the center production well, ultimately increasing the reservoir pore volume available for gas storage as well as recovering additional oil volume. The initial test development wells were drilled, proving the validity of the reservoir characterization, but economic conditions tabled the project.

Optimize Helium Recovery (TX, USA)

NITEC developed a complex reservoir simulation model for the world’s only helium gas storage field. The storage operation is located in a naturally fractured and faulted carbonate formation. NITEC performed an integrated reservoir characterization (stratigraphy, structure, petrophysics, and seismic) as well as using its fracture characterization technology to develop the dual-porosity 4 component compositional simulation model. The model successfully history matched 78 years of operations with over 3,500 pressure points and 7000 gas composition points. The model is still in use today for predicting the helium recovery as the storage field is being depleted and abandoned.