NITEC has broad experience in use of numerical modeling of hydraulically fractured horizontal wells in maximizing asset value.

NITEC’s proven technology and workflow help design and optimize asset development by addressing the following critical decision questions:

- Number of wells per DSU,

- Well landing

- Vertical and horizontal well placement (spacing, staggering)

- Number, type and size of the hydraulic fracture stages,

- Sequence of fracture treatments in pad completions (zippering)

- Placement of infill wells in areas of depletion (infill/offset relationship)

- Implementation of EOR (Feasibility, pilot design, and evaluation, full-field development)

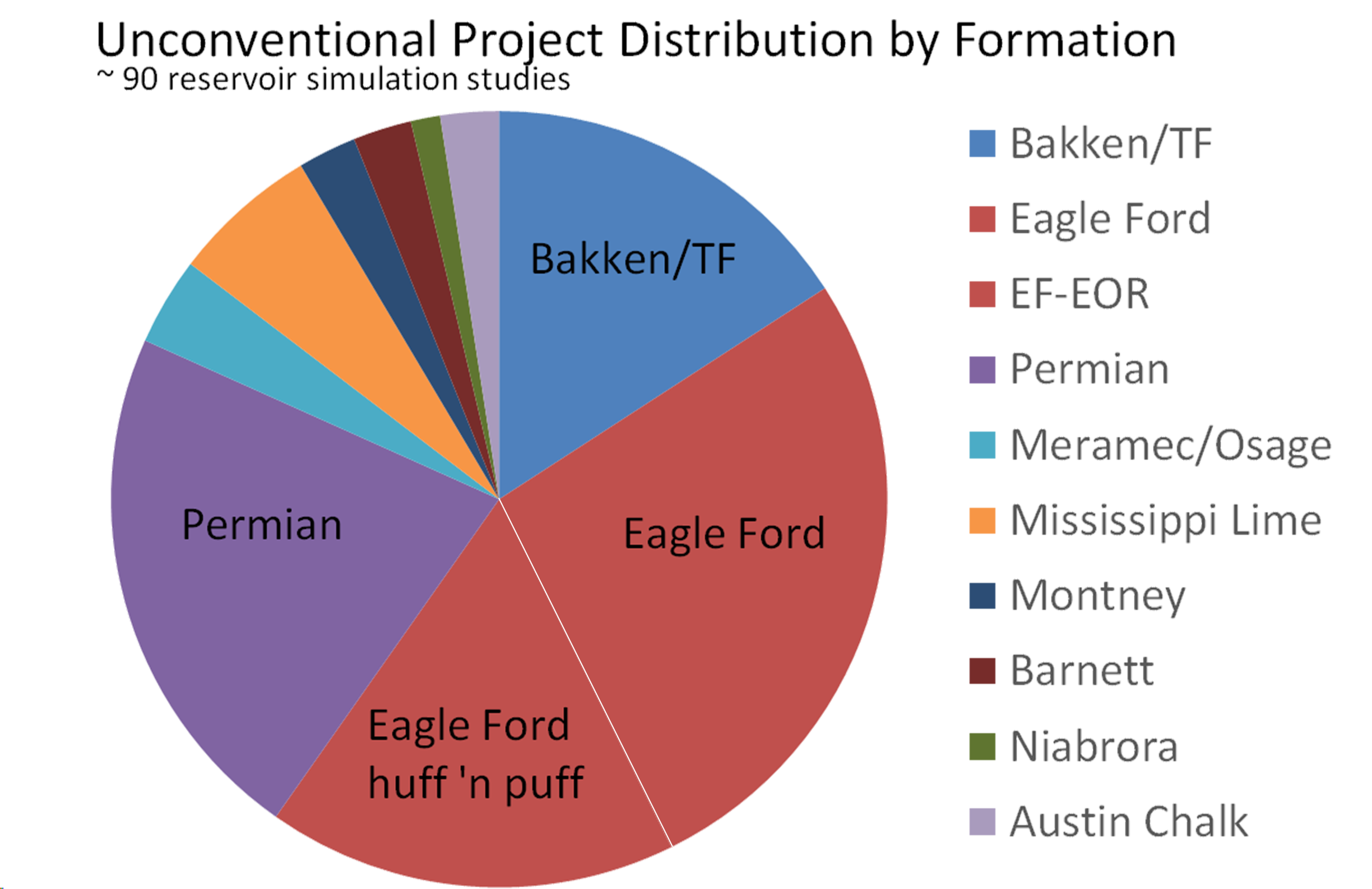

Over 70 reservoir modeling studies have been performed using NITEC’s workflow.

NITEC has applied its workflow successfully to many DSUs in Bakken, Three Forks, Eagle Ford, Barnett, Wolfcamp, Spraberry,3rd Bone Sand and Shale, Mississippi Lime, Niobrara, Montney, Meramec, Osage, Piance, Pinedale and Woodbine formations.

NITEC’s workflow provides a significantly enhanced understanding of the reservoir and well performance through the integration of all the available data. NITEC uses a numerical simulator (RKS-6X) with special geomechanical formulation for modeling of SRV generation within the flow simulator which was developed with NITEC’s guidance. Parameters that influence the SRV generation as a result of both tensile and shear failures are calibrated instead of the SRV itself, making the process seamless. The changes in the SRV size and geometry during production are also handled through the closure parameters that are part of the geomechanical formulation of the simulator utilized.

NITEC’s capability of modeling multiple wells in a DSU makes it possible to resolve frac hits and well interference which reduce the uncertainty on the SRV geometry.

Numerous unconventional resources that were developed with horizontal wells and hydraulic fracturing have been studied in recent years.

Related Projects:

Infill Offset Well relationship (Parent-Child Well), vertical and horizontal interference in Permian:

NITEC investigated the inference impact on well performance and parent-child relationship for a major oil company. Well spacing per section was optimized based on the injected frac volume. The optimum time to introduce the child well after parent production, minimum vertical and horizontal distance from the parent well to minimize the parent’s influence on the child well production were determined. All the optimization was based on a calibrated (history matched) seven (7) well physics-based simulation model in Permian.

Huff and Puff Feasibility in Eagle Ford:

Based on an eight (8) well calibrated simulation model in Eagle Ford, feasibility of huff and puff gas injection for a full field development was investigated. The actual gas injection pilot project was part of the calibration process. The performance under different operational scenarios including injection rates, injection/production sequence, and scheduling were investigated and reported to support the management’s decision.

Frac. size vs. Spacing optimization in Permian:

NITEC’s client needed proper optimization for well spacing and frac size. Through a 6 well simulation model, NITEC provided the optimum spacing and frac size for different benches of the producing formations. Optimum frac sizes and spacing were different for different benches. The client increased capital efficiency by differentiating the completion and spacing practices among the different benches.

Refacing Evaluation in Eagle Ford:

NITEC’s client needed decision support on deciding between refacing existing wells and drilling infill wells in the same area. NITEC provided analysis of both options by utilizing a five well simulation model that is calibrated for reservoir and geomechanical parameters in the area.

Unified EOS generation for Woodford:

A unified EOS model was generated for Woodford shale using 20 samples covering from dry gas to gas condensate.

Well Spacing optimization in Bakken and Three Forks:

NITEC’s client needed an evaluation of different spacing in Bakken and Three Forks development for exploration purposes. Using publicly available data around the exploratory acreage a representative simulation model was calibrated for reservoir and geomechanical parameters. This information was migrated to the exploratory area by changing the reservoir characterization accordingly. Further sensitivities to optimize spacing and landing for this new area were performed.

GOR vs. water production relationship in Permian:

NITEC’s client needed evaluation on the relationship between GOR behavior and water production and water saturation in Permian. NITEC explained the relationship between water saturation, wettability, and GOR through modeling. This knowledge impacted the understanding of the reserves and long term production behavior.

Completion optimization in Eagle Ford:

NITEC’s client needed to improve its completion practices to recover more oil in Eagle Ford. Simulation study led to a design that improved the Infill of an infill well performance such that the new well produced more than the original parent well’s total production within months. The optimization was based on a 4 well history matched simulation model.

Compressor design criteria based on gas injection performance in Eagle Ford:

NITEC’s client needed guidelines to build proper size compressors to be utilized in huff and puff operations at Eagle Ford. Using models created at different depths containing different oil types, operational ranges (pressure and injection rate) of possible huff and puff operations were determined for proper compressor design.

A quick study to evaluate the potential of a field in Permian for acquisition:

NITEC’s client needed a quick evaluation of a field that they were planning to bid on. They used NITEC’s model to understand and evaluate the upside potential by infill drilling and assess the uncertainties associated with the project. The analysis provided by NITEC helped the client’s decision to bid or not on the prospect.

Frac size vs. Spacing optimization in Permian:

NITEC’s client needed proper optimization for well spacing and frac size. Through modeling, NITEC provided the optimum spacing and frac size for different benches of the producing formations. Three reservoir simulation models were generated to create an optimum solution that would represent multiple regions in the area. Improved understanding of the reservoir and the spacing optimization that takes into account the interference supported the client’s decision making on capital spending.

Huff and Puff Pilot Design:

Based on a nine (9) well history matched the model in Eagle Ford, the feasibility of huff and puff gas injection for a full field development was investigated. The operational pressure range, the injection schedule, and the injection rate were optimized to achieve a successful huff and puff pilot in this area to confirm the feasibility and maximize the knowledge.